Late post: this event was conducted at 26th Sep 2013.

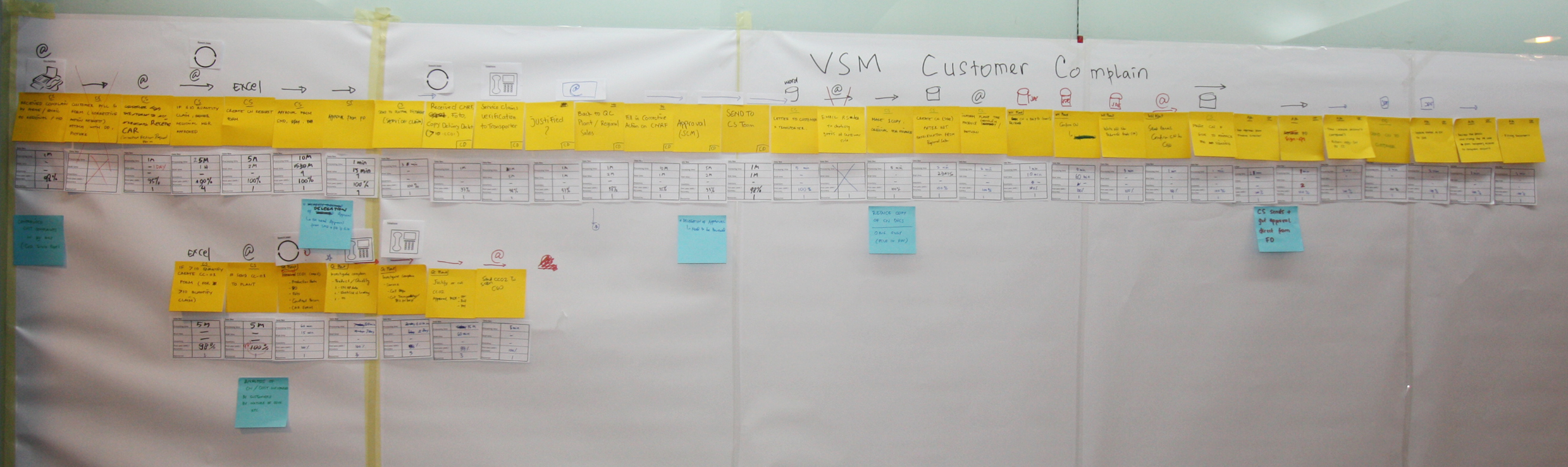

This was kick-off project ENTERPRISE of LEAN for back office through VSM tools (Value Stream Mapping). This project was helped by Genpact, consultant from USA who had experience to support implementation in GE (General Electric).

This workshop and kick-off took 4 days with the real assessment was Revenue and Collection process for the first implementation.

Then, we implemented the following business process:

- Supply chain processes (inventory, production & costing)

- P2P (Procure to Pay)

- Costing

I was appointed as coordinator to implement whole processes with national coverage, Head Office and Plants (Cilegon & Gresik). All the processes were took a year implementation with the fantastic benefits can be delivered to this organization.

Even though this was not easy job and responsibility, I would say thanks for this assignment that I could learn a lot regarding operational excellence and how to increase productivity by reducing wastes and LEAN process.

VSM is interesting tools, like we play in the ground together. Serious but fun…

#ValueStreamMapping #Lean #OperationalExcellence